Using a car lift improperly can lead to serious injuries, damage to vehicles, or costly shop downtime. Car lift safety is essential for preventing accidents such as falling vehicles, structural failure, or workers getting trapped. Adhering to best practices and following a step-by-step approach ensures both safety and efficiency.

Key Keywords and Concepts

- Automotive lift safety

- Car lift operation

- Safe car lift usage

- Maintenance, inspection, weight capacity

- Locking devices, safety locks

Step 1: Choose the Right Car Lift & Inspect Before Use

- Select a lift with an adequate weight capacity

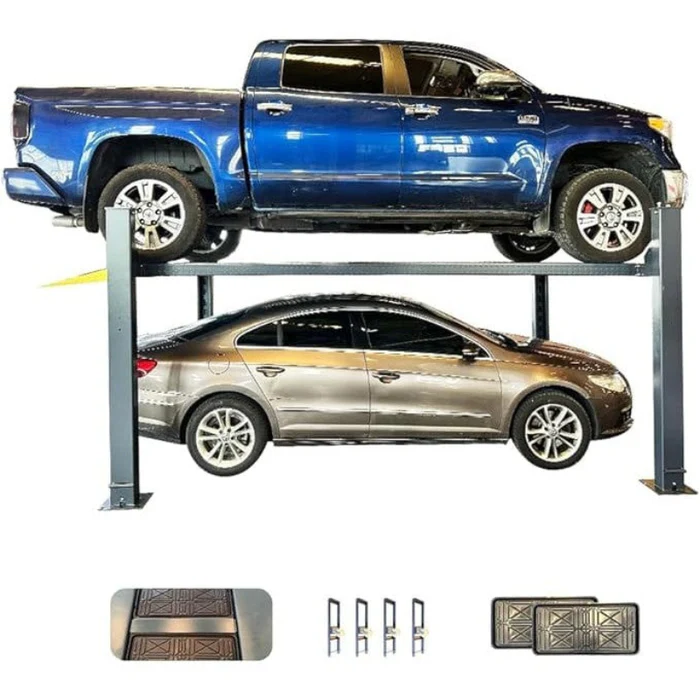

Know the gross vehicle weight rating (GVWR) of the car you’ll lift. Always choose a lift rated well above the car’s weight to maintain safety margin. A hydraulic two-post lift, four-post lift, or scissor lift must match your usage. If you’re shopping or upgrading your lift, this model is a good option to consider. - Perform a safety inspection before each use

Check structural components: columns, arms, lift pads, chains or cables. Inspect for cracks, corrosion, fluid leaks, or worn parts. Ensure the safety locks engage properly. Automotive lift safety demands a walk-around inspection every time.

Step 2: Proper Positioning of the Vehicle

- Align the vehicle properly

Center vehicle between lift posts (or platform) so weight is evenly distributed. Misalignment can cause instability. - Use the correct lift points on the vehicle

Every vehicle has manufacturer-specified lift points (frame rails, jacking points). Using incorrect points can damage body or chassis, and may slip. - Check that the ground/floor is level and the lift is anchored

The lift needs to be installed on solid, level concrete and properly anchored. Even small tilts increase risk of shifting or tipping.

Step 3: Raising the Vehicle Safely

- Lift in incremental stages

Raise the vehicle a few inches, then stop and check stability. Verify that arms are secured, pads are in firm contact, safety locks engage. - Use safety locks immediately

Once at a height where work is to commence, engage the lock mechanism. This prevents collapse due to hydraulic or mechanical failure. Safe car lift operation depends on these devices. - Ensure no one is under the vehicle during lifting

Make sure bystanders are clear; warn everyone around that lift is in use. Always double-check surroundings.

Step 4: Working Under the Lifted Vehicle

- Confirm stability

Give the vehicle a small shake (using hands) after safety locks are engaged to confirm it’s secure. If you detect any movement, lower and reposition. - Use additional support when needed

If doing heavy work or relying on jacks or stands as backups, ensure they are placed correctly and rated appropriately. - Maintain clear communication

If working with a team, ensure all workers know when lifting, lowering, or moving the vehicle. Use signals or verbal cues to avoid missteps.

Step 5: Lowering the Vehicle Safely

- Clear tools and personnel from under the vehicle

Before lowering, make sure no tools, parts, or individuals are underneath. - Disengage locks carefully

Disengage safety locks slowly, making sure the mechanism works smoothly. Then lower the vehicle gradually. - Lower to the ground completely

Once the vehicle is back on solid ground, retract arms and pads. Check for any damage to floor or lift during operation.

Step 6: Maintenance & Periodic Checks

- Regular lubrication of moving parts (arms, pivot points, hydraulic cylinders) to avoid wear.

- Periodic professional inspection (annually or per manufacturer’s recommendation).

- Replace worn or damaged parts immediately: hydraulic hoses, cables, safety pins.

Tips & Reminders for Car Lift Operation

- Always respect the maximum capacity rating of the lift. Overloading is dangerous.

- Never bypass or disable safety features like locks or limits.

- Keep area around the lift clean and free of oil/grease to prevent slipping accidents.

- Ensure proper training: anyone using the lift should know how to operate the controls and understand safety measures.

Conclusion

Using a car lift safely isn’t just about having good equipment—it’s about following correct procedures: inspecting equipment, positioning the vehicle properly, using locks, and maintaining the system. For those in need of reliable equipment or replacement parts that meet automotive lift safety standards, here’s a useful reference to high-quality lifts and accessories.

By following this step-by-step guide and keeping safety as your top priority, you can ensure that your car lift operation is efficient and accident-free. Safe lifting! If you’d like help selecting a specific type of lift (two-post vs four-post vs scissor), I can walk you through pros and cons.